Shop Time Part 6 - Accidental Wine

Posted on April 9, 2025 by Michael Keane Galloway

There are two guava trees on the property that my wife and I currently rent. Our first year living there we couldn’t handle how many guavas these two trees rained down on us. We were so unable to handle the mess that it made that I think the land lord noticed and asked us if we don’t like guavas. I liked them just fine, I just didn’t know how to handle over 50 pounds of guavas.

I made one feeble attempt that first year to gather a few pounds and make guava jam. I ended up pureeing about 5 pounds and unfortunately added too much water while trying to boil it. I then over corrected by adding too much sugar, and ended up making a tougher (and chewier) guava candy instead.

The following year I decided to be strategic and try to use up as many guavas as I could. I decided to do 3 things: 1) take a few pounds of guava to work to give away, 2) pick some to have on hand for lunches (and give them away to my land lord if he came by), and 3) make alcohol.

Originally a coworker had suggested that I could make a sour beer. I looked into that and it seemed like it would be a steep learning curve to try and make a sour beer with no prior brewing experience. Instead, I found recipes for cider making that seemed like it would be more straight forward. I set out to buy the necessary equipment, and froze most of my harvest before attempting to make the cider.

Since I live in California and I was worried about the heat, I ended up picking a strain of yeast that’s commonly used in champagne (more on that later). I also ended up buying a lot of other interesting chemicals like potassium metabisulphate, and pectic enzyme. After everything was gathered, I carefully sanitized everything tossed in all of my ingredients, and then realized that the kit that I bought did not have the appropriate airlock for my brewing bucket. I had to use tape to cover the hole for the airlock and order a next day delivery for half a dozen airlocks from Amazon.

Once I had my airlock and pitched my yeast, we were off to the fermenting races. My home office had a near constant burbling sound, and the rest of the house had a yeasty fermenting smell. I’m just glad that my wife and sister-in-law were willing to put up with it!

Eventually after a week, primary fermentation was finished and I was able to pitch my cider into smaller vessels for secondary fermentation. That secondary fermentation took about a month and during that time, I had something scary happen. A gross white substance formed on top of the cider, and I thought that I had ended up with a moldy batch. Thankfully, there’s a handy flow chart for diagnosing such problems by Doin’ The Most. With that information, I was able to narrow it down to a benign pellicle or a yeast raft.

After tasting it down the road, it was more likely a yeast raft. It also tasted a lot more like wine than I was expecting. I chose to not back sweeten and left the cider still due to fears of creating bottle bombs on my first outing. While I was bottling and tasting the results of secondary conditioning, my wife gave me incredibly high praise saying that it was “surprisingly drinkable!”

I then let it bottle condition for another month before handing it out to some coworkers as a very late holiday gift. I didn’t mention the holidays. I just gave it out at that point.

The following are some pictures that I took during this process.

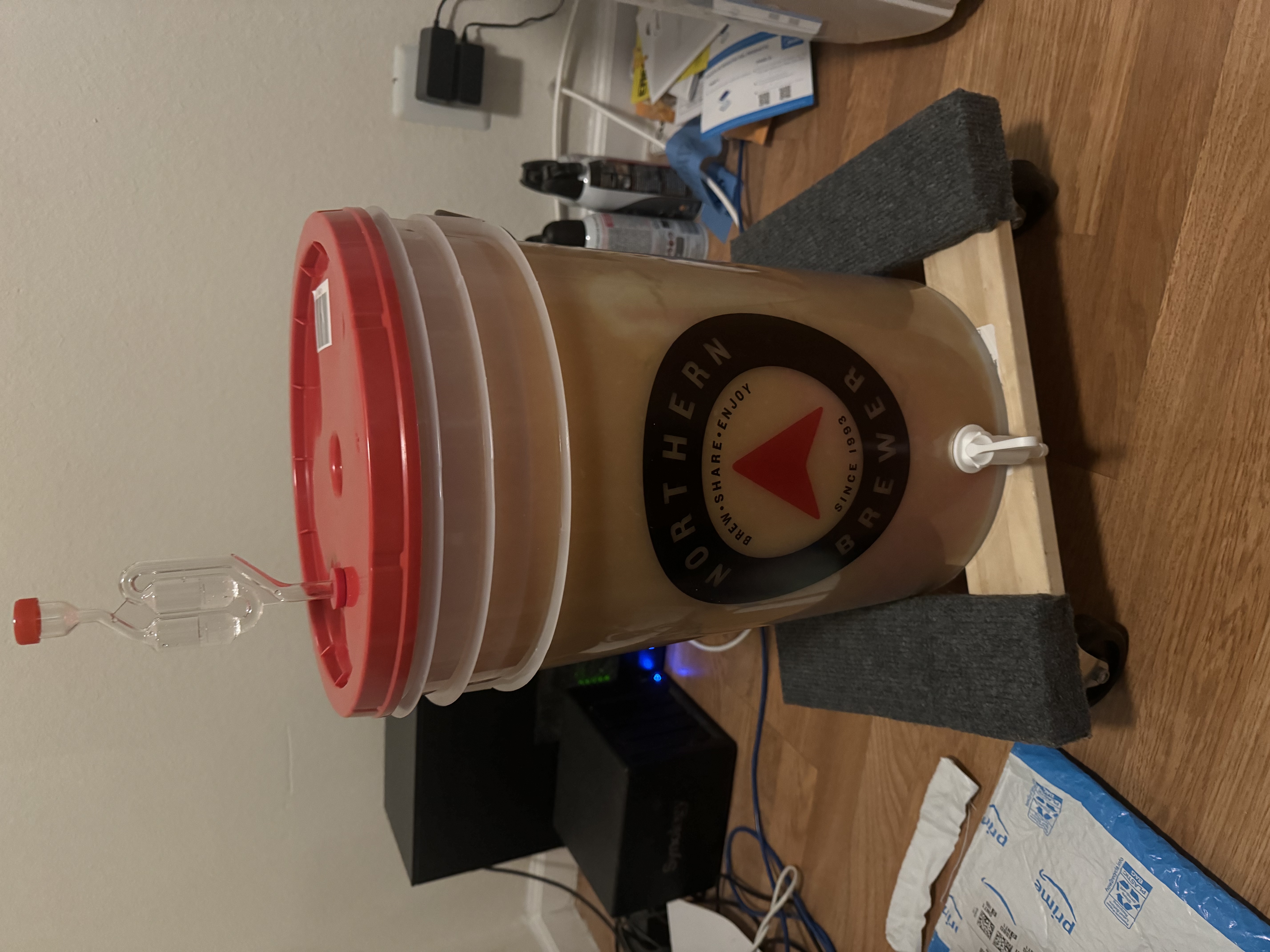

Initial Setup

This was the setup that I had after pitching my yeast the guava and mango nector

sat in this bucket undisturbed for two weeks during primary fermentations.

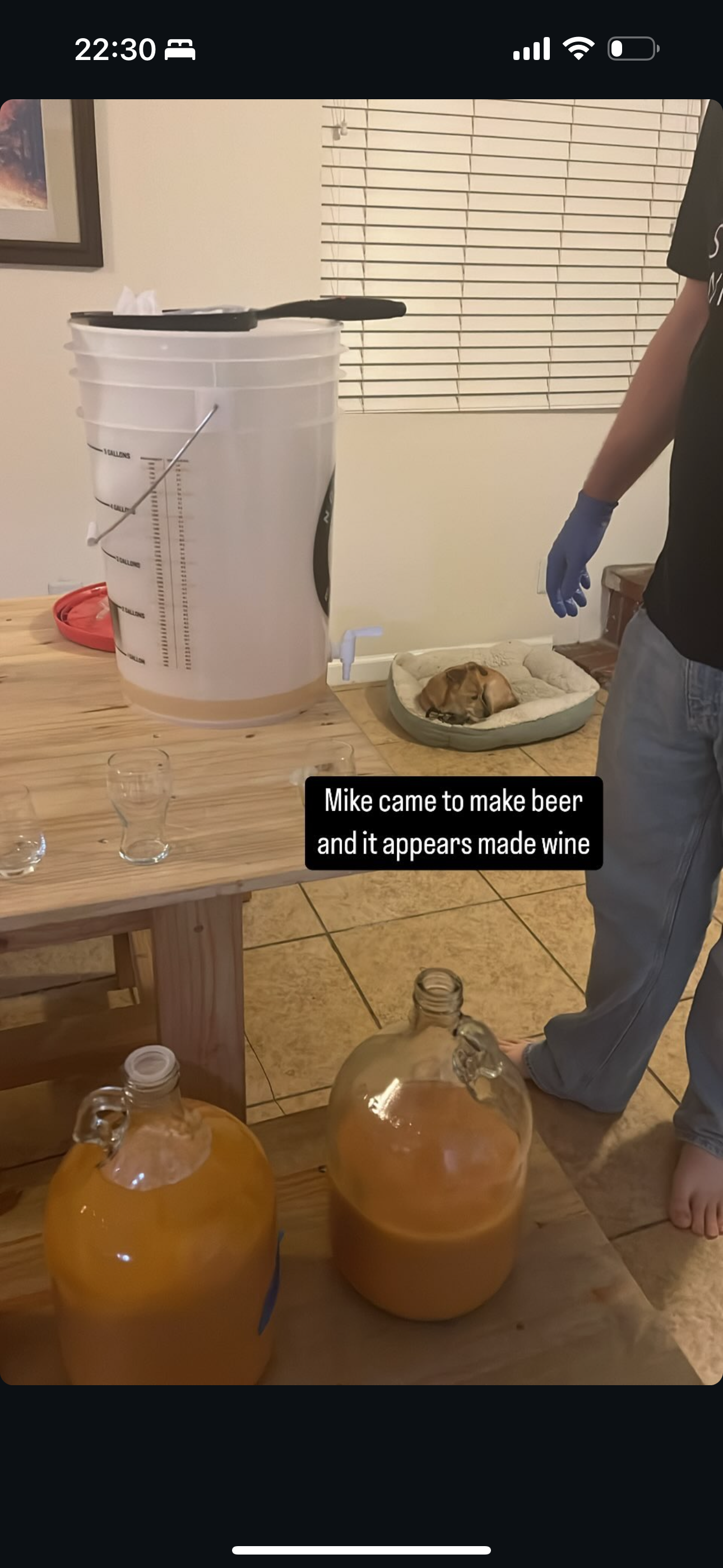

Secondary Firmentation

After a couple of weeks I moved the cider to smaller vessels to be able to see

the progress in clarifying. They stayed in these smaller vessels for at least

1 month. The caption provided by my wife is where I got the title for the article.

Secondary Firmentation relegated to a spare closet

Instead of having these spread out in my office, I moved them to the closet in

our spare bedroom.

Problem Chiled fixed

The jar in the following shot had enough upward momentum from the yeast to blow

out the airlock. I jumped on this fairly quickly resanitized the airlock. Replaced

the water with vodka to help with potential bacteria and poored out some cider

to get headroom.

Bottling

After a month of secondary fermentation/conditioning I syphoned the cider

and bottled it.